China's Premium Asphalt Plant Manufacturer | D&G Machinery Stock Code 1301.HK | Completely Road Construction Solutions Provider, Pursuing Excellence

Home / All / Stone Crushing Plant /

DGR Recycling Series DGR3000T250D 240t/h monoblock recycled asphalt mixing plant

DGR Recycling Series DGR3000T250D 240t/h monoblock recycled asphalt mixing plant

| Categories | Stone Crushing Plant |

|---|---|

| Brand | D&G Asphalt Plant Manufacturer |

| Model | DGR3000T250D |

| Rated capacity | 240T/H |

| RAP proportion | 60-70% |

| mixture storage | By side/under mixer |

| FOB port | TIANJIN |

| Terms of Payment | L/C, D/A, T/T |

| Update Time | Nov 14,2024 |

Detail Information

TECHNICAL DATA

MODEL |

DGR3000T250D |

||

Rated Production Capacity | 240 t/h | ||

Cold Feeder Bin | Number × Volume | 5 / 6 × 18 m³ | |

RAP Cold Feeder Bin | Number × Volume | 3× 12 m³ | |

Dryer Drum | Diameter Ø | ø 2.5 m | |

Length | 9 m | ||

Fuel Type | Diesel Oil/ Heavy Oil / Nature Gas / Coal Powder | ||

Drying Capacity | |||

– Moisture Content 3% | 300 t/h | ||

– Moisture Content 5% | 240 t/h | ||

RAP Dryer Drum | Diameter Ø | ø 1.9 m | |

Length | 10 m | ||

Fuel Type | Diesel / Heavy Oil / Nature Gas | ||

Drying Capacity | |||

– Moisture Content 3% | 120 t/h | ||

– Moisture Content 5% | 100 t/h | ||

Bag Filter | Dust Filtering Method | (1st Stage) Pre-separator + (2nd Stage) Bag Filtering House | |

Mixing Tower | Screening | 5 / 6 | |

Screening Area | 38.4 m² | ||

Hot Bin Quantity | 5 + 1 | ||

Hot Bin Overall Volume | 45 m³ | ||

Aggregates Weighing | 4200 kg | ||

Filler Weighing | 500 kg | ||

Bitumen Weighing | 400 kg | ||

RAP Surge Area | 7 m³ | ||

RAP Weighing Hopper | 2500 kg | ||

Mixing Power | 2 × 55 kW | ||

Mixing Rated Volume | 4200 kg | ||

Mixing Capacity | 336 t/h | ||

Filler Scaling & Feeding | Screw Conveyor With Dual Frequency Conversion, Batching, Continuous Feeding To Mixer | ||

Bitumen Scaling & Feeding | Dynamic 2-Stage Measurement, High Pressure Uniformly Spray. | ||

Mixing type |

Double Shaft/ Twin Motor/ Synchro Twin Reducer |

||

Hot Mix Storage Bin Type | Under Mixer | ||

Hot Mix Storage Bin Capocity | (20 + 20)40 m³ | ||

Bitumen Supply System | |||

Filler Supply System | |||

Control System |

• DGLeap Control System 2.0ontrol System 2.0 • Large Screen Industrial Computer • PLC Touch Screen HMI • Laser Printer • Air-Conditioned Control Cabin |

||

ENVIRONMENT PERFORMANCE |

• Dust Density⩽20mg/Nm³ • Ringelmann Blackness Class 1 • Noise in Control Cabin ⩽70dB |

||

NORMAL OPERATION CONDITION | • Factory Standard • Industry Standard • National Standard • CE Standard • implement the highest standard | ||

The above specifications are for reference only. D&G Machinery reserves the right to make changes in engineering, design and improvement at any time without prior notice or obligation. | |||

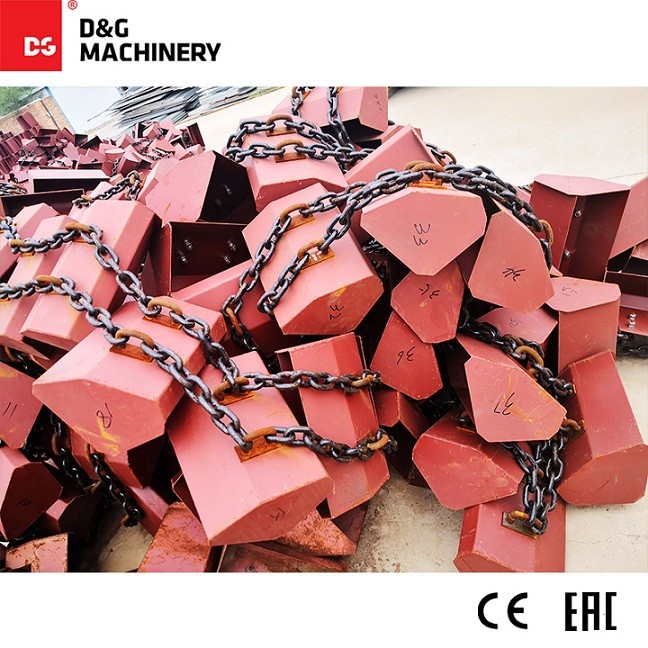

PRODUCT DISPLAY

Review

- Loading...

Leave Your Info, Get the Best Solution Soon!

Interested in becoming a distributor? Please fill out this form and we will contact you for further discussion.

- Name

- Tel

- *Title

- *Content