China's Premium Asphalt Plant Manufacturer | D&G Machinery Stock Code 1301.HK | Completely Road Construction Solutions Provider, Pursuing Excellence

RCS150 RAP Tooth Roller Crushing and Screening Equipment

| Categories | Stone Crushing Plant |

|---|---|

| Brand | D&G Asphalt Plant Manufacturer |

| Model | RCS150 |

| Model | RCS150 |

| Designed through capacity | 150 t/h |

| Water content | ≤3% |

| Maximum particle size | ≤80mm |

| Origin of place | China |

| Motor power | 44kW(22kW×2) |

| RAP Milling material | ≤35mm 60% |

| Brand | D&G MACHINERY |

| FOB port | TIANJIN |

| Terms of Payment | L/C, D/A, T/T |

| Update Time | Apr 20,2024 |

Product feature

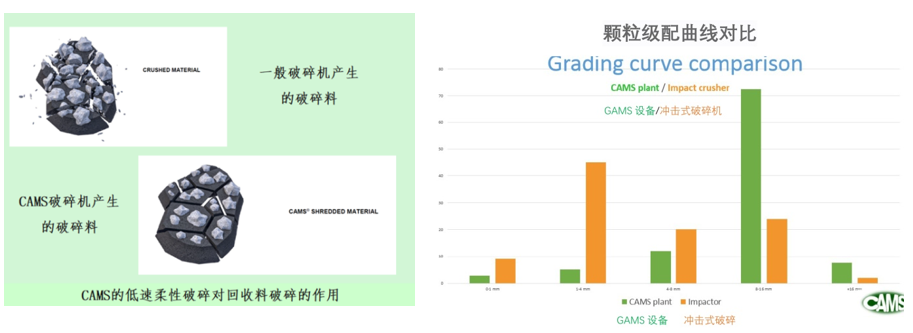

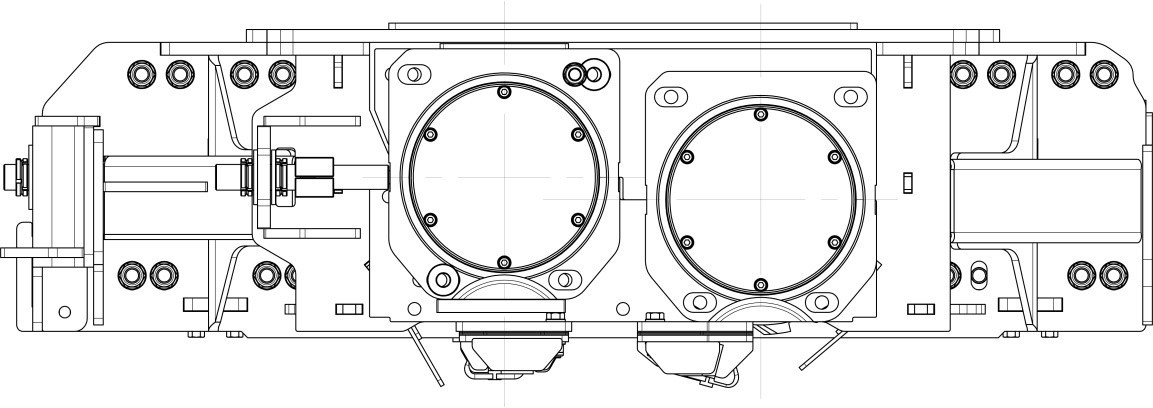

As the pavement recycled material crushing and screening equipment needs to be used with the asphalt mixing plant, it needs to be relocated according to the asphalt mixing plant. Therefore, the tooth roller type crushing and screening equipment adopts a fixed and modular design, which is convenient to install and easy to relocate.

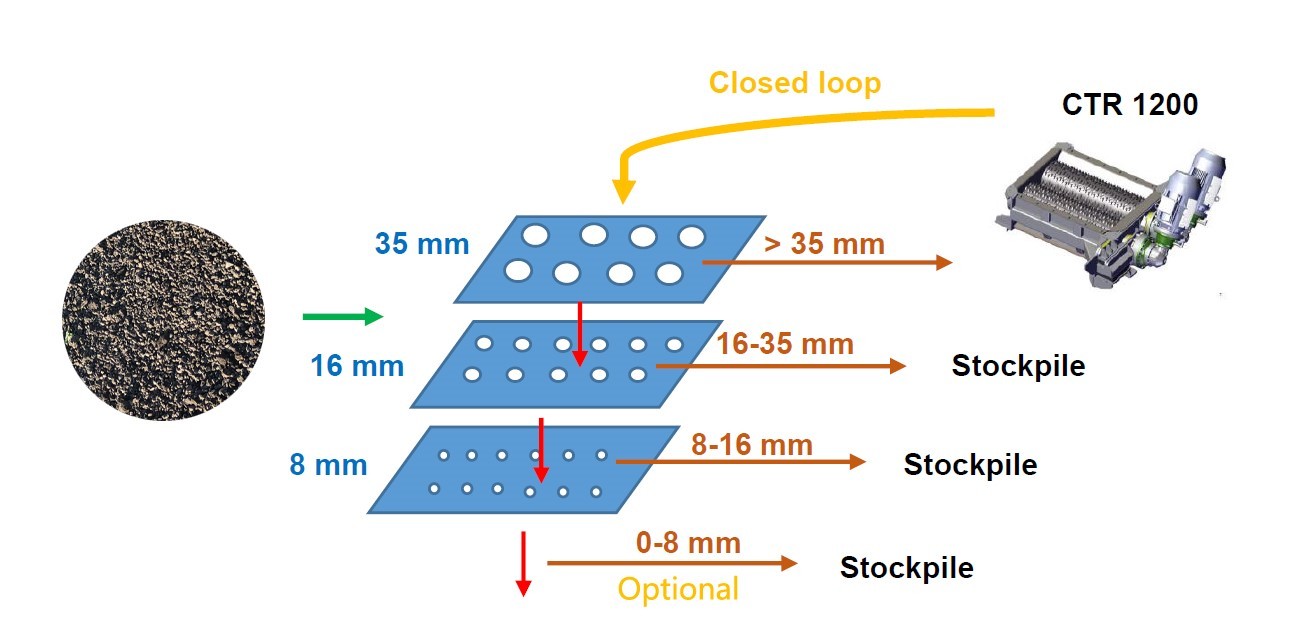

Because the milling material already contains a large amount of fine material, the RAP tooth roller type crushing and screening equipment adopts the process of screening first and then shredding, that is, the closed-loop process of screening the milling materials first, crushing the oversized materials and screening again.

|

Name

|

RAP tooth roller crushing and screening equipment

|

||

|

Model

|

RCS150

|

||

|

Capacity

|

150t/h

|

||

|

Rated operating conditions

|

|||

Aggregate | RAP milling material (≤35mm 60%,Maximum particle size ≤80mm) | ||

Moisture content | ≤ 3 % |

- Loading...

Leave Your Info, Get the Best Solution Soon!

- Name

- Tel

- *Title

- *Content