DGXR Recycled Material Application: Switchable Combination, Born for “Recycling”

01 Innovative Switchable Combination

Featuring a “Monoblock” design, recycling becomes a “standard configuration” of the asphalt mixing plant.

This innovative approach moves away from the traditional concept of adding “recycling function” later, while enabling cold/hot recycling combination, parallel-flow/counter-flow options, various addition proportions options. The maximum RAP addition ratio can reach 100%.

02 Comprehensive Optimization of the Main Tower Structure

The mixer is located in the center of the “Monoblock” plant to ensure that the recycled materials and new aggregates required can be fed into the mixer directly through respective weighing hoppers.

Less tower height with less ground occupied, structure compact design.

03 Coarse/Fine RAP Materials Separation to Alleviate the Adhesion of Recycled Materials and Asphalt Aging

There is a RECYCLING RING (D&G Machinery patented technology) on the recycling dryer drum. The coarse and fine materials are heated separately to maximize the value of RAP.

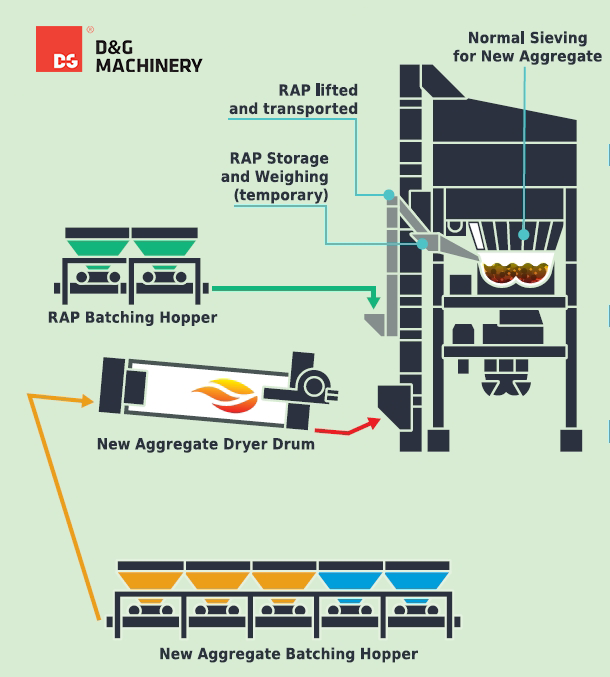

04 Cold RAP Added to Mixer-Less Cost, Higher Quality

After the RAP is extracted from the cold hopper, it enters a specified RAP surge bin via belt conveyor and elevator.

There is the RAP weigher at the bottom of the surge bin. The RAP is directly delivered to the mixer after weighing.

The RAP mainly absorbs the heat of the new aggregate during mixing to reach the required the temperature. The recommended RAP adding ratio is 15-20%.

D&G Machinery is professional to offer RAP solutions, including but not limited to DGXR asphalt plant. If you have any further queries, please do not hesitate to contact us.