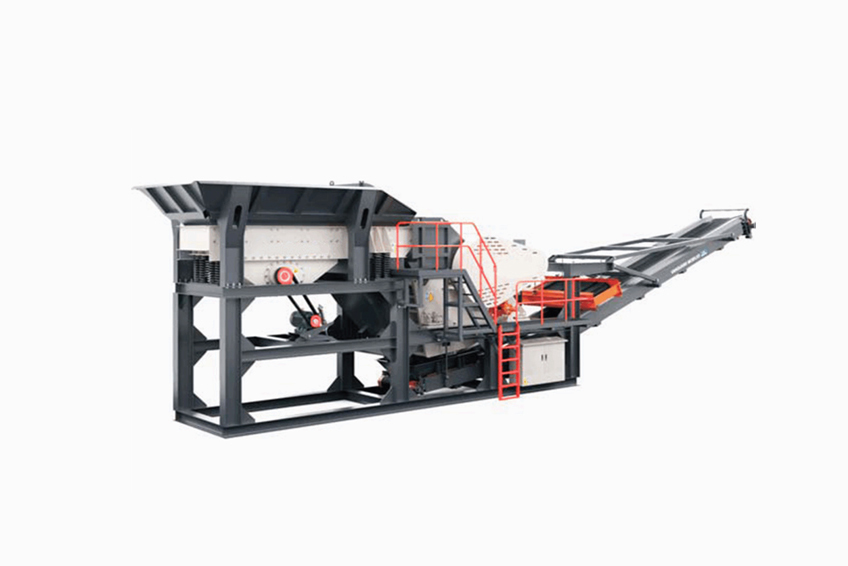

The Stone Crushing and Screening Plant is an essential setup in the construction and mining industries, designed to process raw stones into usable aggregates. This facility plays a pivotal role in producing materials such as gravel, sand, and crushed stones, which are crucial for various construction projects, including roads, highways, and buildings.

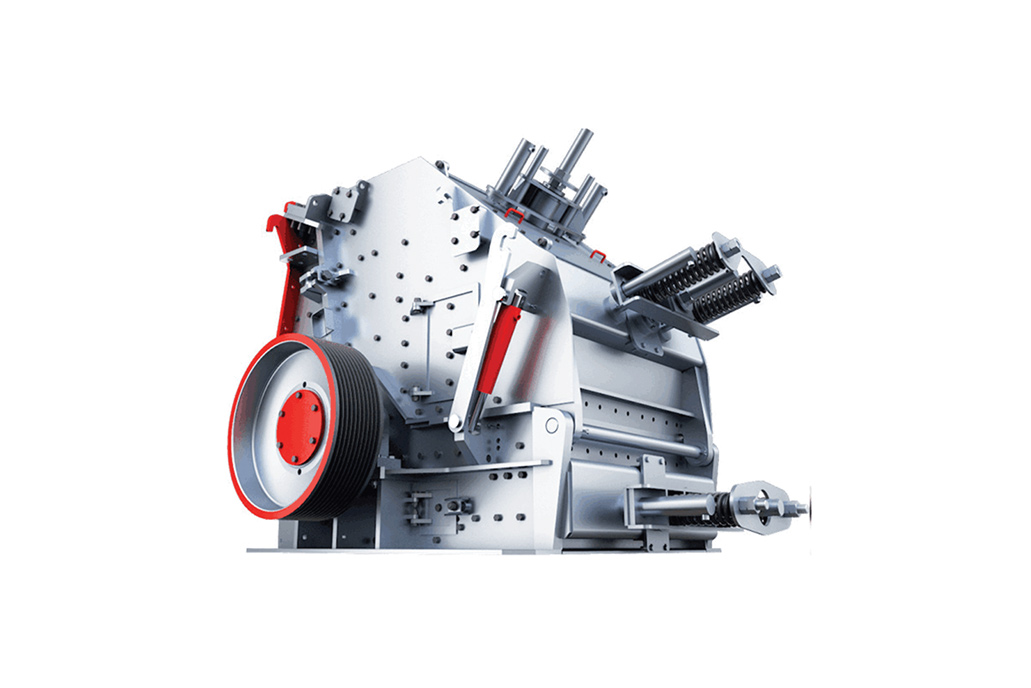

Typically, a stone crushing plant consists of several key components, including jaw crushers, cone crushers, impact crushers, and screening equipment. Each of these machines performs a specific function in the process of breaking down large stones into smaller, more manageable pieces while ensuring that the final product meets quality standards.

The first stage involves the extraction of raw stones from quarries, which are then transported to the crushing plant. As the stones enter the facility, they undergo pre-screening to remove any impurities before being fed into the crushers. The crushers employ different methods of fracture. For instance, jaw crushers use compression, while impact crushers utilize high-speed impacts. This diversity in crushing mechanisms allows for the production of various sizes and grades of aggregates.

Once the stones are adequately crushed, they are conveyed to screening units. Here, vibrating screens sort the material based on sizes, ensuring that only the desired sizes proceed to the next stages. Effective screening is critical as it directly impacts the quality of the aggregate produced. Additionally, dust suppression systems are often integrated within the plant to minimize airborne particulate matter, addressing environmental concerns associated with stone processing.

Moreover, the efficient design and layout of a stone crushing and screening plant contribute to its operational effectiveness. Many modern plants incorporate automation and control systems, allowing for improved monitoring of production processes and reductions in operational costs. As a result, the stone crushing and screening plant stands as a cornerstone of sustainable construction practices, enabling industries to meet growing demand for high-quality aggregate materials while adhering to environmental regulations.

Content Disclaimer

The content provided on this website is for informational purposes only. Some of the information, articles, images, and other materials available on this site may be sourced from third-party websites and public domain resources. While we make every effort to ensure the accuracy and reliability of the information, we do not take responsibility for the content provided by external sources.