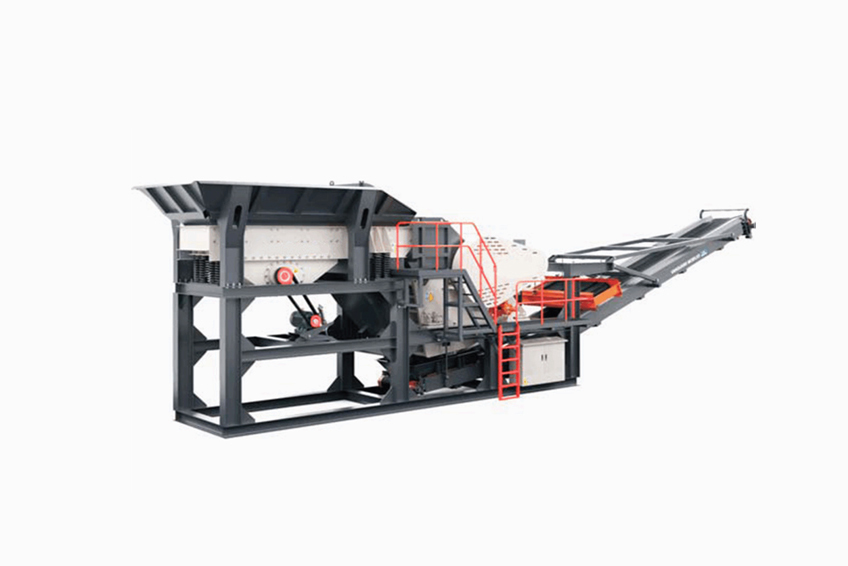

A stone crushing plant layout typically involves a systematic arrangement of various components designed to facilitate the efficient processing of raw materials into finished products. The fundamental aim of such a layout is to maximize productivity while minimizing operational costs and ensuring environmental compliance. The essential elements of a stone crushing plant include a feeder, crushing units, screening equipment, and a conveyance system.

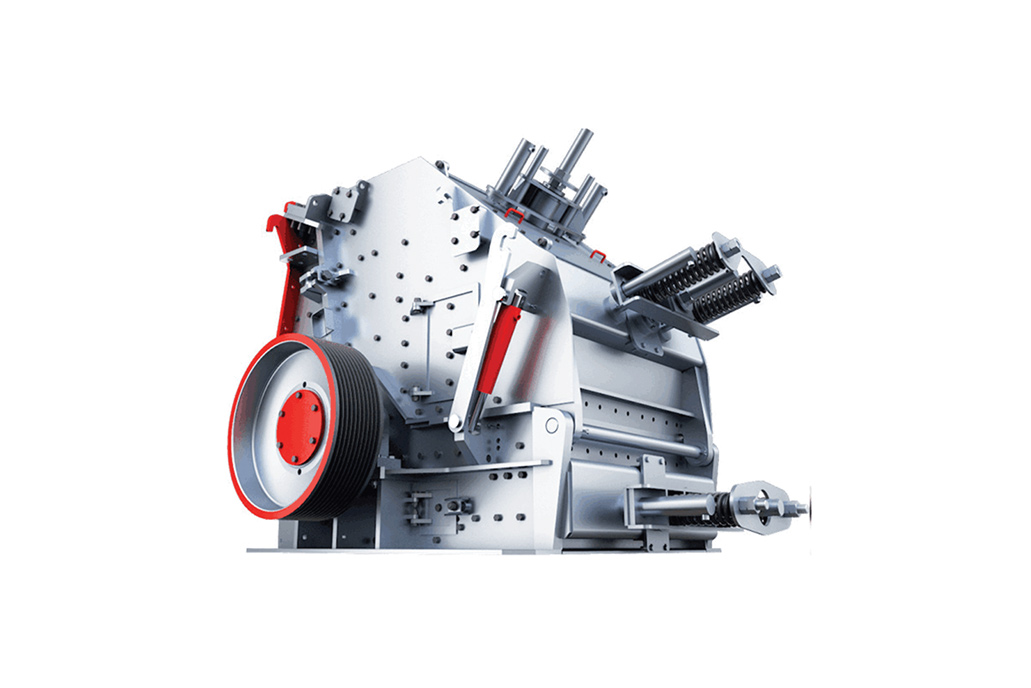

The feeder plays a crucial role in controlling the flow of raw materials to the crushers. It is essential for maintaining optimal throughput and preventing bottlenecks in the operation. The crushers are the heart of the plant, where the size reduction process occurs. Depending on the desired end product, different types of crushers may be employed, such as jaw crushers, cone crushers, and impact crushers. Each of these crushers serves a specific purpose and produces different sizes and shapes of aggregate material.

After the initial crushing, the material typically moves to a series of screening units, which are essential for sorting the crushed stone into various grades. The layout must consider the arrangement of these screens to maintain an efficient workflow, as well as the subsequent transport of sorted products.

Conveyors are integral to the plant layout as they facilitate the movement of material between different stages of the process, thus enhancing the overall efficiency of the operation. A well-designed layout will minimize the need for manual handling and reduce the potential for material spillage, which is crucial for maintaining a clean and safe working environment.

Additionally, the layout should incorporate necessary control systems to monitor the operation and ensure compliance with health and safety regulations. Consideration for dust suppression and noise reduction is also critical in the design process, especially for facilities located in or near populated areas. Overall, an optimized stone crushing plant layout enhances operational efficiency, optimizes resource utilization, and contributes to the economic viability of the crushing operation.

Content Disclaimer

The content provided on this website is for informational purposes only. Some of the information, articles, images, and other materials available on this site may be sourced from third-party websites and public domain resources. While we make every effort to ensure the accuracy and reliability of the information, we do not take responsibility for the content provided by external sources.