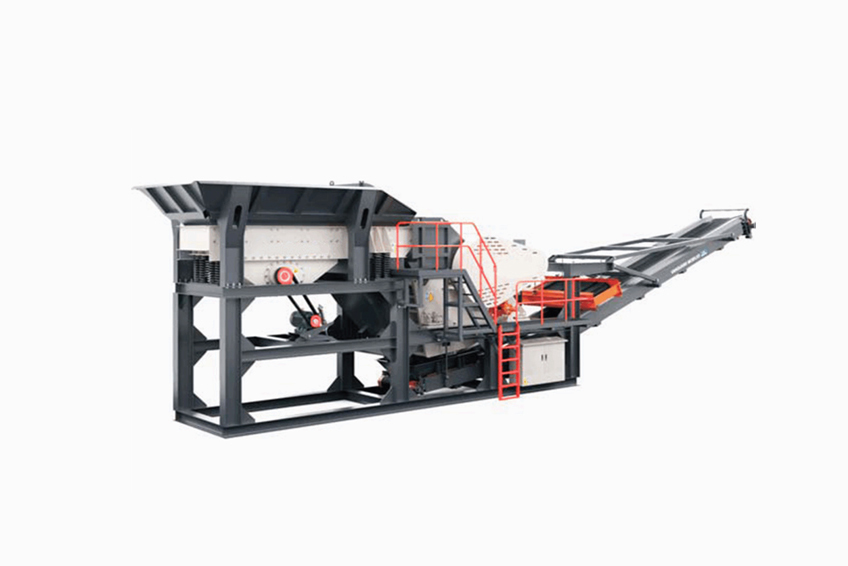

A stone crushing plant is a crucial setup for transforming raw materials into aggregates required for construction and various industries. The primary machines involved in this process are jaw crushers and cone crushers, both of which serve distinctive yet complementary purposes in the production line.

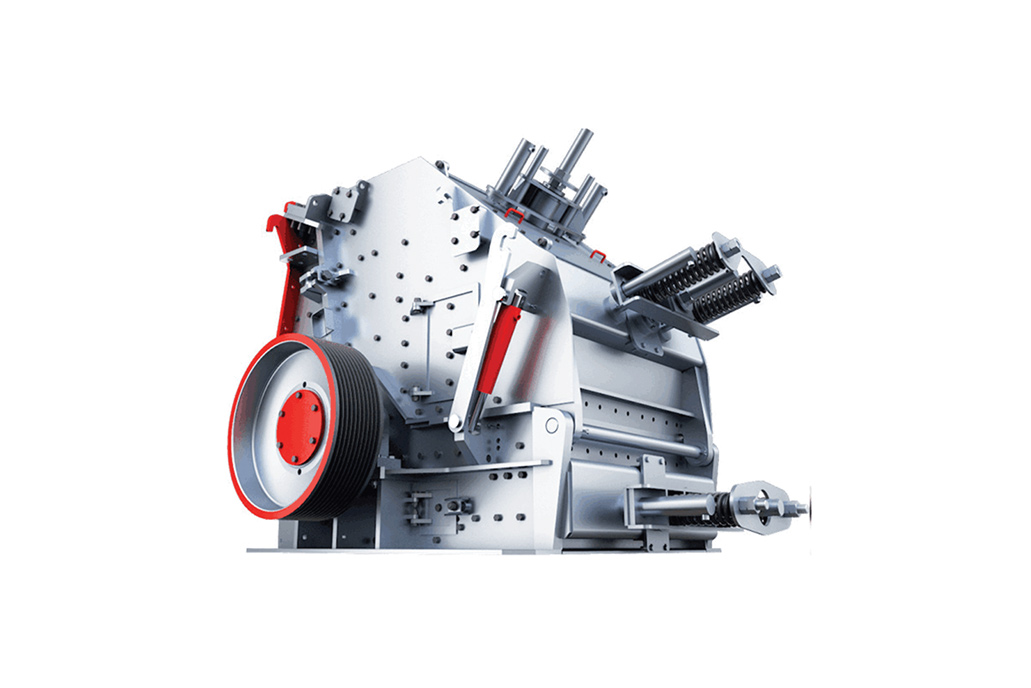

Jaw crushers are typically the first stage in the crushing process, used to break down larger rocks into smaller, manageable pieces. The robust design of jaw crushers allows them to handle hard materials with ease, making them essential for managing the initial phase of material processing. The primary advantage of using a jaw crusher is its ability to produce a high reduction ratio, resulting in a more significant size reduction of large stones to smaller aggregates, which can then be further processed. This stage not only enhances the efficiency of the overall crushing process but also helps in reducing the energy consumption of subsequent stages.

Following the jaw crusher, cone crushers are employed for additional size reduction and refinement of the material. These crushers are renowned for their ability to produce finer aggregates, essential for high-quality construction materials. The design of cone crushers allows for adjustability, enabling operators to modify the output size as required. This features ensures flexibility in production, allowing the plant to meet varying customer demands.

Additionally, a stone crushing plant integrated with both jaw and cone crushers leads to a streamlined process where the raw input continuously moves from one stage to another with minimal downtime. In a modern stone crushing plant, these machines work in harmony to ensure the efficient conversion of raw stone into usable materials, maximizing productivity and enhancing profitability. Ultimately, the combination of jaw and cone crushers forms the backbone of a stone crushing operation, providing the necessary strength, efficiency, and versatility needed in today’s construction environments.

Content Disclaimer

The content provided on this website is for informational purposes only. Some of the information, articles, images, and other materials available on this site may be sourced from third-party websites and public domain resources. While we make every effort to ensure the accuracy and reliability of the information, we do not take responsibility for the content provided by external sources.