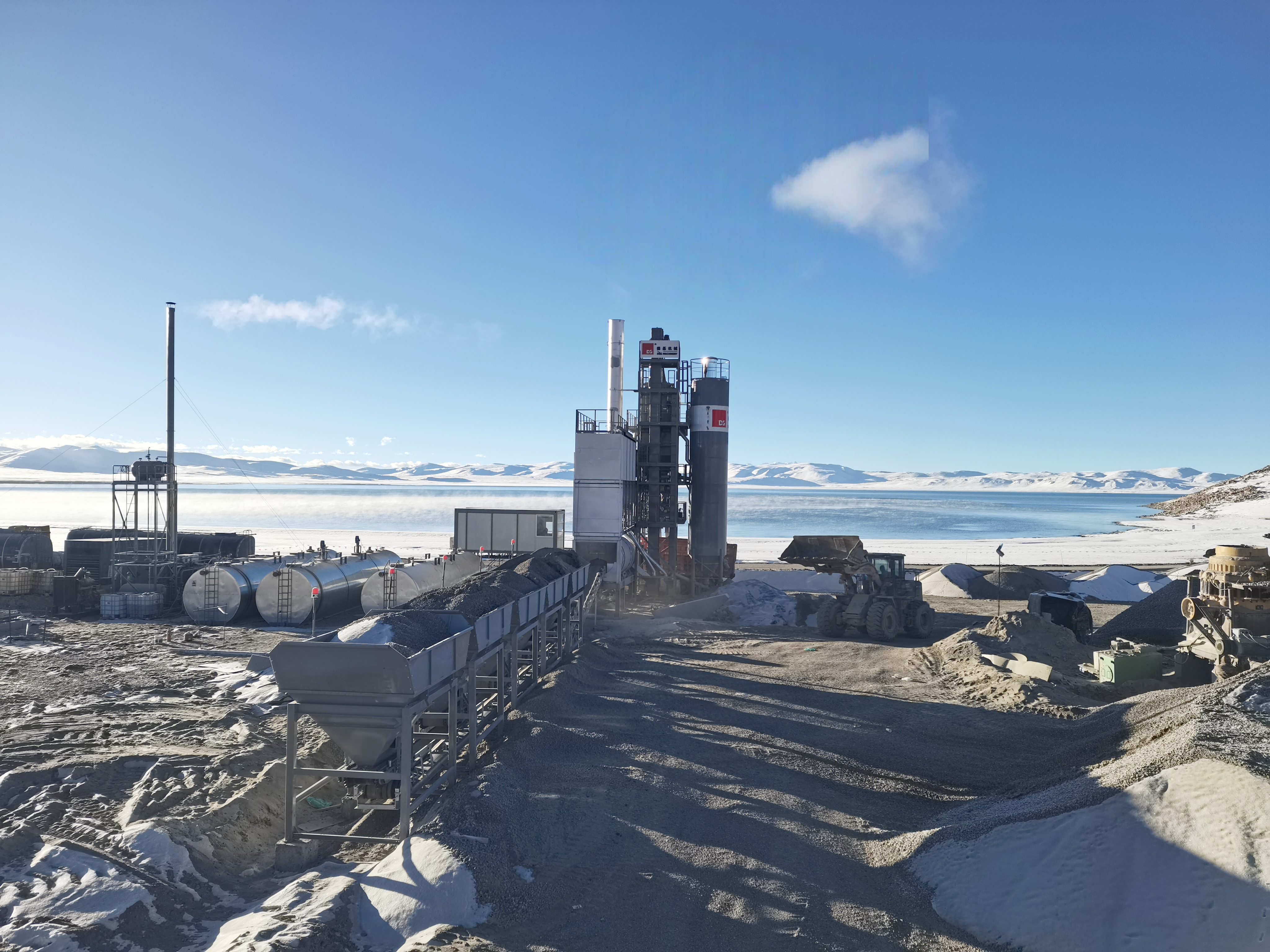

D&G Machinery's DG2500 Asphalt Mixing Plant Stands Tall Atop the Snowy Plateau

In Tibet, the closest place to the sky, a D&G Machinery DG2500 asphalt mixing plant has been put into operation. Like an awakened "steel giant," it is injecting new momentum into this sacred land. This is not just an ordinary equipment installation, but a challenge to extreme environments, a refinement of product quality, and a profound interpretation of professional ethics.

Pushing the Limits: The Harsh Tests of the High-Altitude Environment

Tibet, known as the "Roof of the World," presents significant challenges to any industrial activity due to its unique high-altitude environment. The Najin region, at an altitude of nearly 5,000 meters, suffers from thin air with an oxygen content only 60-70% of that at sea level; intense ultraviolet radiation is unrestricted; and there are extreme temperature differences between day and night. Such an environment poses an extremely severe challenge to large-scale machinery and equipment:

·Difficulty "breathing": Low air pressure and low oxygen content can lead to a decline in fan performance, incomplete combustion, and challenges to the power output of the equipment.

·"Body temperature" imbalance: The huge temperature difference places extremely high demands on the stability of metal materials, hydraulic systems and electrical components.

·"Endurance" depletion: Strong ultraviolet rays can accelerate the aging of non-metallic components such as rubber seals and pipelines, while wind and sand may penetrate into the precision parts of the equipment.

Superior Adaptability: The "High-Altitude Genes" of the DG2500

Faced with such demanding conditions, the D&G Machinery DG2500 was not an unprepared "newcomer." From its initial design, it incorporated features to handle various complex working conditions, and underwent specific adaptive optimizations for high-altitude environments.

1. Enhanced Power System: The power system of the equipment is optimized to ensure stable and sufficient power output even in low-oxygen environments, thus guaranteeing the robust "heart" of the core components of the mixing plant.

2. Improved electrical system stability: Electrical components and control systems have anti-interference capabilities, ensuring accurate command transmission and stable and reliable operation even under drastic temperature changes.

3. Structural and material optimization: Key structural components are made of low-temperature resistant, high-strength steel to effectively resist cold brittleness; seals and pipelines are made of materials with better weather resistance to delay aging.

4. Intelligent control and protection: The integrated intelligent control system can monitor equipment operating parameters in real time, automatically adjust the working status according to environmental changes, and has fault warning and self-protection functions to prevent problems before they occur.

It is precisely because of these built-in "hard power" features that the DG2500 dares to stand tall on the snowy plateau and demonstrate its excellent adaptability to the high-altitude environment.

Dedication and Contribution: The "Plateau Spirit" of the D&G Service Team

If equipment represents hard power, then the installation service team dispatched by D&G to Najin, Tibet, represents the most impressive "soft power" of this mission. They exemplified true professionalism through their actions:

·Overcoming physical limits: Service engineers must first conquer altitude sickness—headaches, insomnia, and difficulty breathing. They carry oxygen tanks, yet never stop working. The "high-altitude red" on their faces is their badge of honor.

·Meticulous Installation: Despite the harsh climate, they strictly adhered to installation specifications, paying meticulous attention to the tightening torque of every bolt, the quality of every weld, and the levelness calibration of every component. They understood that on the plateau, the reliability of the equipment was crucial to the success of the entire project.

·Combining wisdom and experience: Faced with unexpected problems that may arise on site, they quickly analyze and make decisive decisions based on their rich experience and technical expertise, resolving the installation challenges brought about by the high-altitude environment one by one.

·Dedication and Responsibility: They are far from their families, stationed on the front lines of the project, solely to ensure that the DG2500 can be installed and commissioned on schedule, safely, and with high quality, and put into production as soon as possible. Their figures represent the most steadfast guardianship beneath the snow-capped mountains.

At this moment, D&G Machinery is not merely installing a piece of equipment, but also etching a profound mark of Chinese manufacturing's courage to face challenges, its ability to overcome difficulties, and its commitment to promises onto the snowy plateau. D&G Machinery looks forward to exploring green value symbiosis with Tibet, contributing powerful momentum to its transportation construction and economic development.