D&G Machinery Empowers Hot Recycling Upgrading for Monoblock Asphalt Plant

In recent years, with the growing call for sustainable development and increasingly strict environmental protection requirements, the upgrading and retrofitting of asphalt mixing plants have become increasingly important. Leveraging years’ expertise in asphalt mixing plants, D&G Machinery has launched a patented new-generation “self-cleaning” dryer drum with independent R&D. After implementation in many projects, D&G Machinery’s RAP dryer drum retrofitting service has proven effective with remarkable results, winning widespread praise from customers.

Chengdu customer specializes in the construction of municipal engineering projects such as pavement construction and maintenance. Adhering to the philosophy of meticulous construction and exquisite service, it maintains a competitive position in the industry. To achieve sustainable development, Chengdu Ruixin has decided to upgrade and retrofit its current DGR4000 monoblock asphalt mixing plant, thus promoting low-carbon development, enhancing production efficiency, reducing energy consumption, and achieving economic benefits.

After

Work Together to Overcome Difficulties

After careful consideration of factors such as brand reputation, reliability, and after-sales service, Chengdu customer finally chose D&G Machinery's retrofitting and upgrading solution. From preliminary site inspection, working condition design, production and manufacturing, to delivery and installation, D&G Machinery has been providing Chengdu customer with a complete set of retrofitting services aimed at achieving high-proportion RAP addition, meeting customer needs, and addressing their pain points.

Increase Output, Promote Transformation

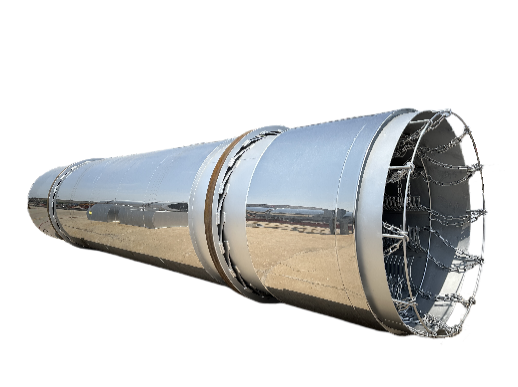

The key to the successful retrofitting of this asphalt plant lies in upgrading the original RAP recycling drum with a rated capacity of 120-160t/h to D&G Machinery's new-generation 160-200t/h "self-cleaning" RAP dryer drum. The corresponding supporting equipment was also upgraded, such as enlarging the RAP elevator to accelerate the feeding, ensuring that the equipment maintains high output, saving production costs and increasing economic benefits, while improving the quality of the asphalt mixture. After the overall upgrade, particularly with the enhanced production capacity, the customer said, "We are very happy to see the capacity increased. The upgraded RAP drum is much more convenient to use as well. We don’t need to climb inside for daily cleaning anymore."

RAP Recycling Technology, Core Competence

The "self-cleaning" dryer drum stands out as D&G Machinery's latest-generation RAP drum, featuring further optimized structural design innovations. These upgrades facilitate the formation of a more uniform material curtain, ensuring more even heating of the recycled materials and improving overall thermal efficiency. Additionally, the cleaning cycle of the drum has been extended, bringing a smoother workflow, easy operation, and a large increase in production efficiency.

Advantages after Retrofitting:

●A significant increase in RAP addition rate, enabling substantial recycling of old materials with less cost.

●The innovative structural design facilitates the forming of a more uniform material curtain, ensuring even heat distribution throughout the recycled material thus lifting overall thermal efficiency.

●Gentle heating for RAP entering the drum. The maximum discharge temperature of recycled material can reach 170℃, and the exhaust gas temperature can be controlled within 10℃ higher than the discharge temperature.

●The dryer drum's cleaning cycle can be extended by 3-5 times, with the longest cleaning cycle only once per year.

●It can be flexibly integrated with the original plant with larger capability to utilize a large amount of RAP.

The upgrading and retrofitting of Chengdu customer's asphalt mixing plant represent more than just a technological breakthrough and advancement; it is also a demonstration of the company's commitment and responsibility towards sustainable development. D&G Machinery will consistently and proactively collaborate with customers to meet their needs for upgrading and retrofitting with technological expertise. We strive to offer customers a wider range of options, from equipment total solutions to retrofitting service and more.