Foamed Bitumen Cold Recycling Technology: An Innovative Engine for Green Highway Maintenance

Guided by the "dual carbon" goals, the highway maintenance industry is undergoing a technological transformation centered on green and low-carbon practices. As an innovative benchmark in the field of recycling technologies, foamed bitumen cold recycling technology is sparking a nationwide technological revolution in China with its unique process advantages and remarkable environmental benefits, injecting new momentum for sustainable development into highway maintenance.

Technical Principle: Mechanical Foaming - The Wisdom of Physical Changes

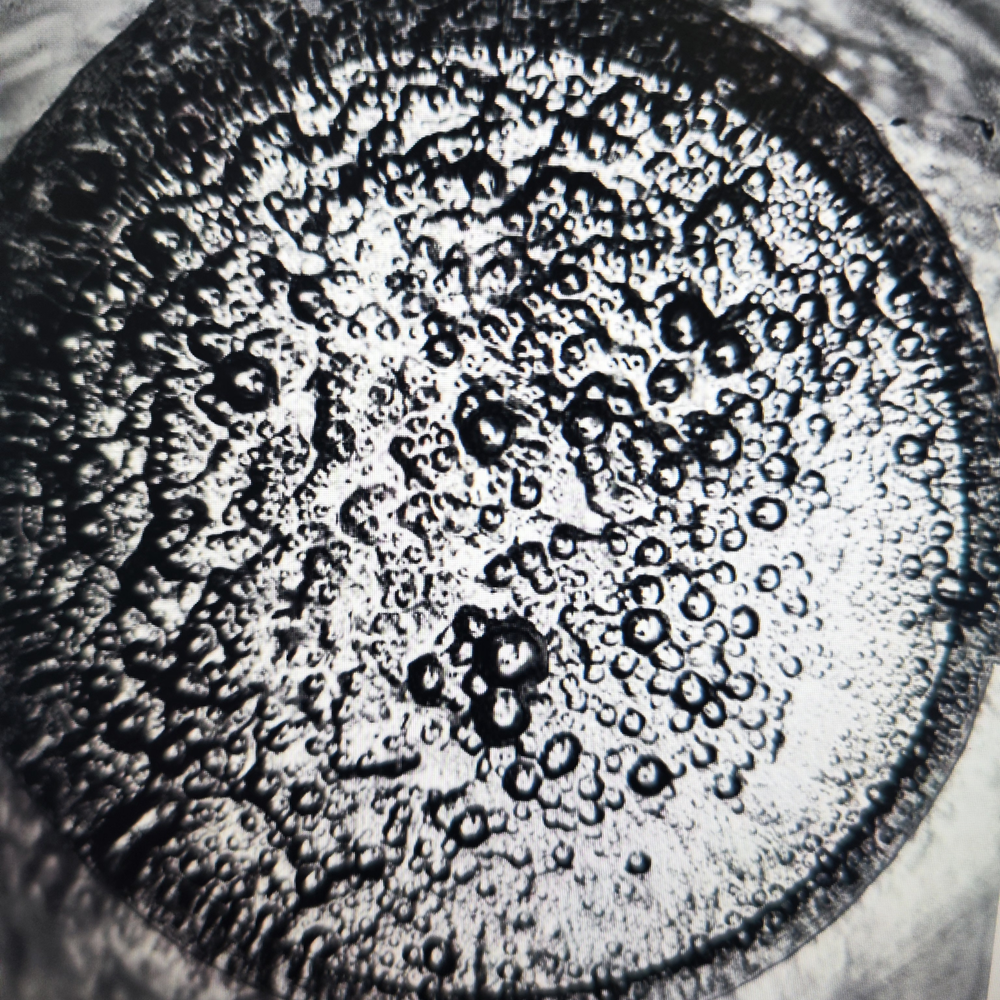

The core of foamed bitumen cold recycling technology lies in the physical foaming process of bitumen. When room temperature water comes into contact with high-temperature bitumen above 150°C, it instantaneously vaporizes, forming tens of thousands of tiny bubbles that expand the bitumen volume by over tenfold, creating foamed bitumen. This specially formed bitumen can uniformly coat the coarse and fine aggregates from reclaimed asphalt pavement (RAP), forming a mortar-like cementitious layer that fills the gaps between coarse aggregates, constructing a composite structural layer that combines both rigidity and flexibility.

Industry Impact: Leading a New Paradigm in Maintenance

This technology has developed a comprehensive system, spanning from equipment R&D to construction specifications. D&G Machinery, as a pioneer in the green asphalt road construction, has actively responded to national policies and industry requirements. Leveraging its own business strengths and focusing on low-carbon and sustainable development goals, we have unveiled a self-developed continuous mechanical foaming device.

The foaming and mixing unit of this device adopts static mixing technology, featuring no moving parts, which makes it simple, reliable, and maintenance-free, thereby saving costs. It utilizes a high-precision plunger-type variable pump that enables frequency conversion control, ensuring stable flow and precise control. The device employs a "Flow + Time" water volume control scheme, offering flexible control and a wide adjustment range. The fully automated control system is easy to operate. It can be seamlessly integrated with the existing control systems of water-stabilized batching plant from different manufacturers, eliminating the need for human intervention during production and achieving true fully automated production control.

Reshaping Maintenance Value

The "Technical Specifications for Highway Asphalt Pavement Recycling " issued by the Ministry of Transport of the People’s Republic of China clearly defines the design standards for foamed bitumen cold recycling mixtures, accelerating the standardization process of this technology.

This technology enables a high proportion of RAP to be recycled. Compared to the traditional milling and repaving process, material costs can be saved. Additionally, as it does not involve heating aggregates and uses ambient-temperature mixing instead, energy consumption would be significantly reduced. The characteristic of operating at ambient temperature extends the seasonal construction window. Foamed asphalt mixtures also feature excellent performance regarding fatigue resistance and high-temperature stability, effectively preventing reflective cracking and extending the service life of pavements.

Foamed bitumen cold recycling technology is not only an innovative practice in material recycling but also a vivid demonstration of the China highway industry's commitment to the philosophy that "Lucid waters and lush mountains are invaluable assets." D&G Machinery will continue to support China's highway development, injecting green elements into the sustainable progress of building a strong transportation nation.