D&G Machinery Asphalt Mixing Plant Retrofitting Series-Hot Recycling Upgrade

With higher environmental protection requirements and the widespread adoption of asphalt recycling technology, owners and users are increasingly recognizing the value of hot recycling. RAP (Reclaimed Asphalt Pavement) recycling brings additional revenue to asphalt plants, making high-ratio hot recycling applications an industry trend. Hot recycling retrofitting has become the most cost-effective solution for aging equipment to keep pace with industry development. However, hot recycling retrofitting faces many challenges:

- RAP tends to stick to dryer drum walls and rake teeth, requiring frequent cleaning that lowers production efficiency;

- Low thermal efficiency, unstable discharge temperature and rapid heat loss result in lower RAP addition ratio and finished product quality;

- High exhaust gas temperature brings significant energy waste and poses fire risks;

- Poor compatibility, hard to meet various needs

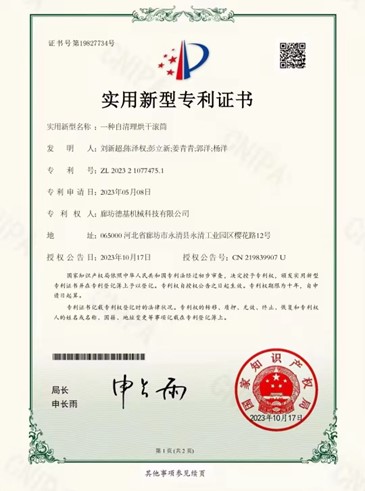

Since launching the first double-drum recycling system in 2003, D&G Machinery has introduced a new-generation "self-cleaning" RAP dryer drum with 22 years’ technical expertise. This patented product has unique structure design, enabling the formation of a "continuous and stable material curtain" within the RAP dryer drum. It has effectively resolved industry common problems while empowering customers with efficient, eco-friendly, and low-cost asphalt mixture production.

D&G Machinery Hot Recycling Upgrade-Core Technical Advantages

1. Self-cleaning Design, Easy Maintenance- Featuring an innovative internal drum structure, the system minimizes RAP adhesion, extending the cleaning cycle to just once annually. This innovation significantly reduces maintenance costs and downtime.

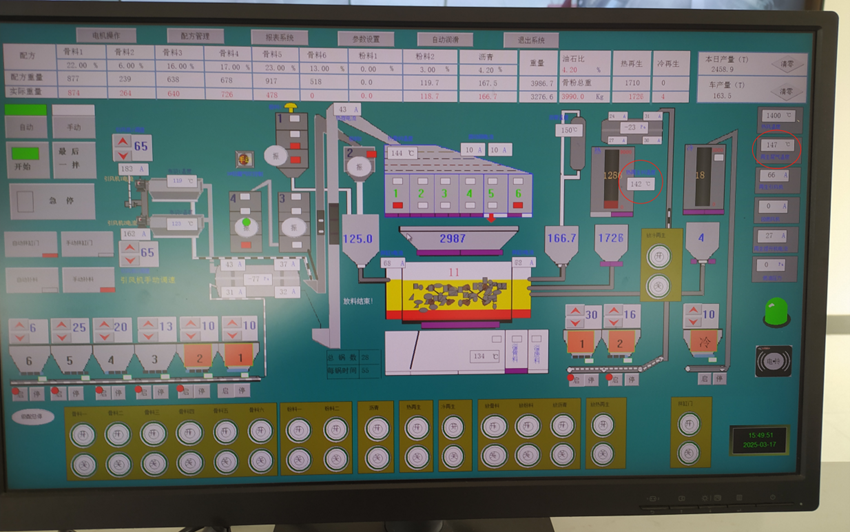

- 2. Uniform Material Curtain, Higher Thermal Efficiency and Precise Temperature Control

- The internal layout has been optimized to form a consistent, uniform material curtain, enhancing RAP heat absorption, boosting thermal efficiency while lowering exhaust gas temperature. The discharge temperature of recycled materials can reach up to 170℃, while the exhaust gas temperature is controlled within a ±10℃ range, preventing overheating and ensuring high quality of the mixture.

- 3. Higher RAP Addition Ratio, Controllable RAP Heating Temperature

- 4. Customizable Retrofitting, Strong Compatibility

- Compatible with both D&G and third-party asphalt plants, offering customized upgrade solutions (with basic/premium configurations) to achieve performance breakthroughs at minimal costs.

Key Post-Upgrade Benefits

1. EconomicalHigh-ratio RAP recycling, reducing raw material costs and strengthening corporate competitiveness

2. Higher Energy Efficiency

Improved thermal efficiency, less energy consumption

3. Environmental Compliance

Exhaust gas enters the primary drum for secondary combustion, minimizing emissions and energy waste, aligning with national environmental protection standards

4. Extended Durability

Extended maintenance intervals by 300%-500% (3-5 times), maximizing equipment utilization

Customer Feedback on D&G Machinery Retrofitting Solution

Customer

Plant

Before

After

Customer in Hubei, China

China Domestic Brand 5000-model Asphalt Plant

RAP addition ratio: 25%

Production capacity: 300t/h

High exhaust gas temperature and material sticking to drum

At the same production capacity, RAP addition ratio reached 40%, with uniform material curtain heating. The temperature differences between discharge material and flue gas are ±5°C, with significant improvement in cleaning efficiencyCustomer in Hebei, China

China Domestic Brand Hot Air Furnace Dryer Drum

RAP addition ratio: 40%

Discharge temperature: 150℃

Exhaust gas temperature reduction: 30-40°C

Production capacity increase: 20-30 t/hCustomer in Shanxi, China

D&G Machinery 4000-model Monoblock Recycling Asphalt Plant

First-generation cleaning structure, periodic manual cleaning required. Discharge temperature: 110℃

Significant improvement in cleaning efficiency, discharge temperature can reach 150℃Post-upgrade Cleaning

Post-Upgrade Discharge Temperature

Leading the Industry Future with Technology

D&G Machinery is committed to technological innovation and service upgrades in asphalt mixing plant. The new-generation RAP dryer drum not only inherits our DNA of Higher Efficiency, Reliability, and Eco-friendly, but also empowers diverse asphalt plants with patented technology and flexible retrofitting solutions, delivering strong momentum for hot recycling applications.

Choosing D&G Machinery Hot Recycling means Choosing:

- Expertise: Constant innovation in asphalt plant technology

- Efficiency: High-performance recycling systems

- High RAP Addition

- Life-long ServiceYou will get:

- Industry-leading self-cleaning Technology

- Tailored low-cost Upgrade Service

- Market-validated reliable recycling solutions

Join D&G Machinery in building a bright and sustainable future!